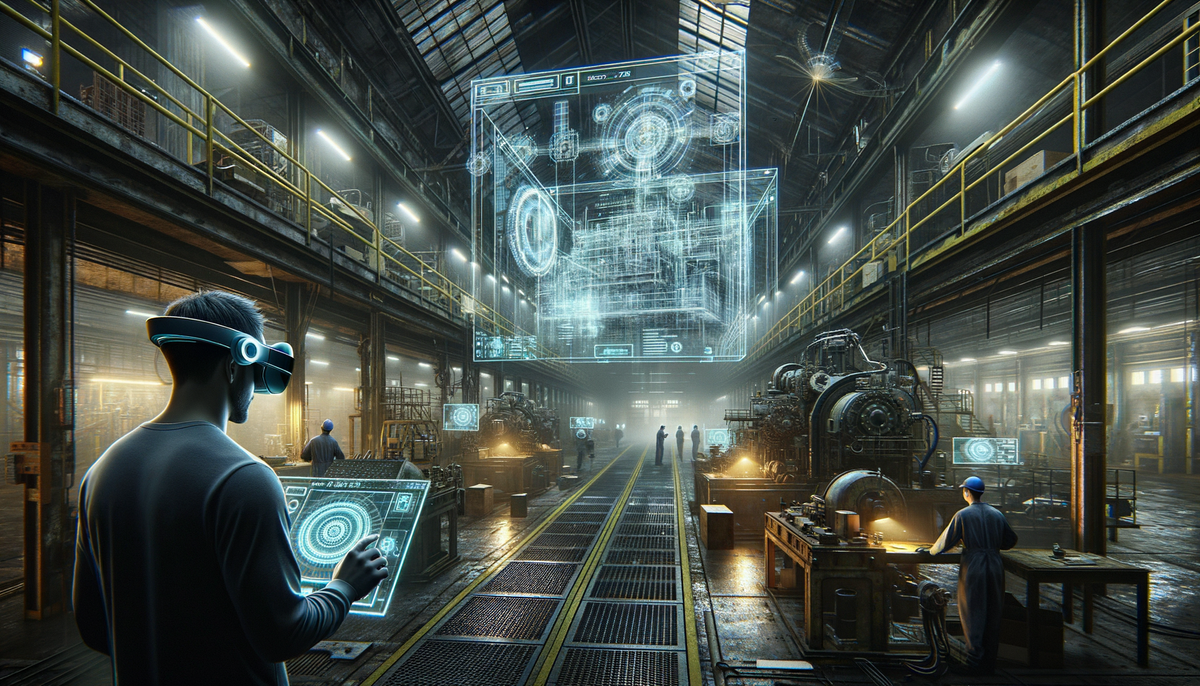

The Potential of Augmented Reality in Industrial Applications

Augmented Reality (AR) has evolved significantly in recent years, transforming various industries by Enhancing productivity, efficiency, and safety. In industrial sectors, AR offers numerous possibilities that can revolutionize traditional processes. This blog post explores the potential of Augmented Reality in industrial applications and how IT is shaping the future of manufacturing, maintenance, training, and more.

What is Augmented Reality?

Augmented Reality (AR) is a technology that overlays digital information, such as images, videos, and 3D models, onto the real world. By using AR devices such as smartphones, tablets, and AR glasses, users can see and interact with this digital content in real time, creating an immersive experience.

Benefits of Augmented Reality in Industrial applications

1. Enhanced training and Skill Development

One of the primary uses of AR in industrial applications is for training and skill development. Traditional training methods such as manuals and on-the-job training can be time-consuming and less effective. AR provides immersive and interactive training experiences that can significantly improve retention and understanding.

For example, AR can simulate complex machinery operations, allowing trainees to practice in a virtual Environment before handling real equipment. This reduces the risk of accidents and ensures that employees are well-prepared to perform their tasks efficiently.

2. Improved Maintenance and Repair

Maintenance and repair tasks can be daunting, especially for complex machinery. AR offers a solution by providing step-by-step visual instructions superimposed directly onto the equipment. Technicians can use AR glasses to receive real-time guidance, reducing the chances of errors and speeding up the repair process.

Moreover, AR can facilitate remote assistance, where experts can guide on-site technicians through complex repairs using AR overlays. This not only saves time but also reduces downtime and Operational Costs.

3. Streamlined manufacturing Processes

In the manufacturing industry, Precision and efficiency are crucial. AR can enhance manufacturing processes by providing real-time data and instructions to workers on the assembly line. For instance, AR can display assembly instructions, highlight components, and even detect defects in real time, ensuring that products meet quality standards.

AR can also optimize inventory management by providing real-time updates on stock levels and locations. This eliminates the need for manual inventory checks and ensures that materials are readily available when needed.

4. Enhanced Product design and Development

AR can revolutionize product design and development by allowing designers to visualize and interact with 3D models of their creations in a real-world Environment. This enables them to identify design flaws and make improvements early in the development process, reducing the need for costly prototypes.

Additionally, AR can facilitate Collaboration among team members by enabling them to share and review designs in a virtual Environment, regardless of their physical location. This accelerates the design process and fosters Innovation.

5. Improved safety and compliance

safety is a top priority in industrial environments, and AR can play a significant role in Enhancing workplace safety. AR can provide real-time hazard alerts, safety protocols, and emergency procedures, ensuring that workers are aware of potential risks and know how to respond.

AR can also assist in compliance by providing real-time information on regulatory requirements and ensuring that workers adhere to safety standards. This reduces the likelihood of accidents and helps organizations maintain a safe working Environment.

challenges and future prospects

While the potential of AR in industrial applications is immense, there are challenges that need to be addressed. High implementation costs, technical limitations, and the need for specialized skills are some of the barriers to widespread adoption.

However, as AR technology continues to advance and become more accessible, these challenges are likely to diminish. The future prospects of AR in industrial applications are promising, with ongoing developments in AR hardware and software, increased investment in AR solutions, and growing demand for efficient and innovative industrial processes.

Conclusion

Augmented Reality is poised to transform industrial applications by Enhancing training, maintenance, manufacturing, design, and safety. As AR technology continues to evolve, its impact on the industrial sector will only grow, leading to increased productivity, efficiency, and Innovation. Embracing AR can provide a competitive edge and drive the future of industrial operations.