Smart Factories: Embedding AI in Industrial Engineering

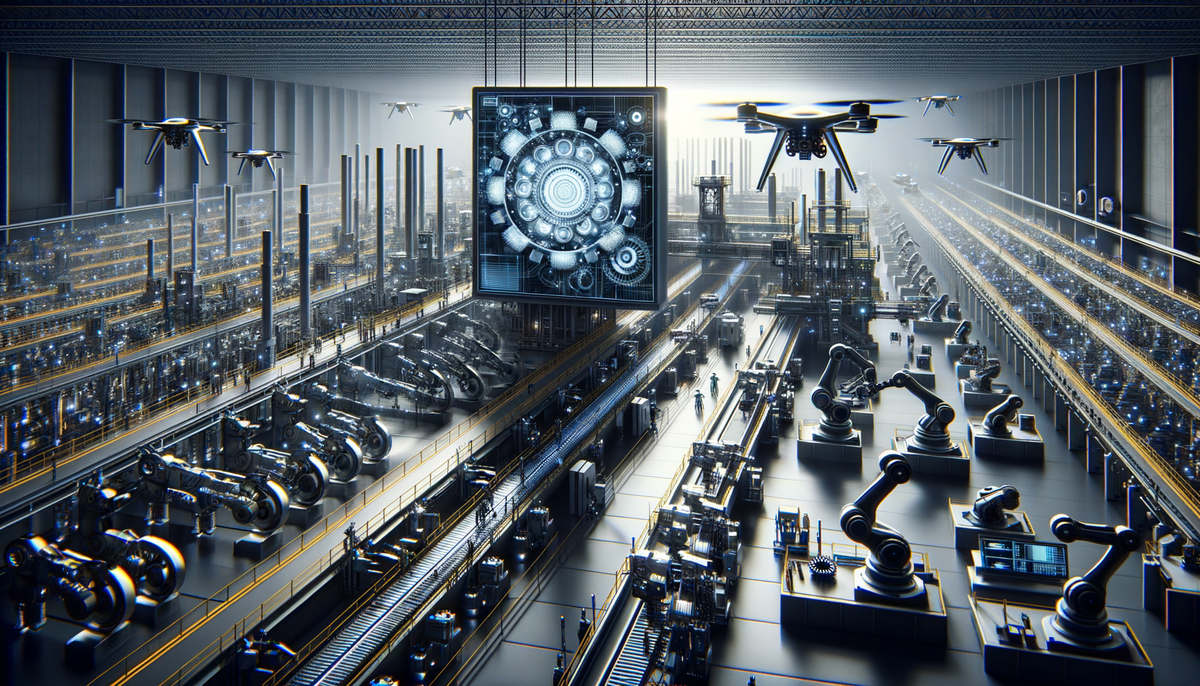

In today's fast-paced industrial Environment, Innovation is key to maintaining a competitive edge. One of the most transformative advancements in recent years is the integration of Artificial Intelligence (AI) into industrial Engineering, giving rise to what we now term Smart Factories. This concept transcends traditional automation by leveraging the power of AI to optimize, predict, and enhance industrial processes across the board. Welcome to the future of manufacturing!

Understanding Smart Factories

A Smart Factory is essentially a digitally networked Environment that leverages data, machine learning, and IoT (Internet of Things) to optimize production lines, supply chains, and overall factory operations. Unlike traditional factories, which rely on linear processes and human intervention, Smart Factories use AI algorithms to make decisions in real-time. This fundamentally changes how we approach manufacturing tasks, from equipment maintenance to resource allocation and beyond.

Benefits of AI integration in Industrial Engineering

-

Enhanced productivity: AI-driven systems can analyze vast amounts of data at speeds unattainable by human workers. This leads to faster decision-making, reducing downtime and maximizing output.

-

Predictive Maintenance: One of the most powerful applications of AI in Smart Factories is predictive maintenance. Instead of waiting for machinery to break down, AI algorithms can predict potential failures and suggest preventative measures, thereby saving time and reducing repair costs.

-

Quality Control: AI can significantly improve Quality Assurance processes. machine learning algorithms can detect anomalies in products with greater accuracy than human inspectors, ensuring higher quality and consistency.

-

Supply Chain Optimization: AI can predict Supply Chain disruptions and optimize logistics in real-time, ensuring that resources are available when needed and reducing delays.

-

cost savings: Through predictive maintenance, resource optimization, and enhanced productivity, companies can significantly reduce Operational Costs, ultimately leading to higher profit margins.

technologies Powering Smart Factories

Several emerging technologies play a crucial role in the development and functioning of Smart Factories. Here are some key ones:

1. Artificial Intelligence (AI)

AI is at the core of Smart Factory operations, driving automation, machine learning, and data analytics. Algorithms can optimize workflows, forecast demand, and even guide robotic manufacturing processes.

2. Internet of Things (IoT)

IoT connects various factory devices and sensors, enabling real-time data collection and monitoring. This interconnected Environment allows for seamless communication between different parts of the manufacturing process.

3. Big Data Analytics

The vast amounts of data generated in Smart Factories need to be processed and analyzed. Big Data Analytics helps in extracting actionable insights, which can further optimize various processes.

4. Robotics

Advanced Robotics, combined with AI, provide unparalleled Precision and efficiency in manufacturing tasks. Robots can work alongside humans, taking over repetitive and dangerous tasks, thereby improving overall safety and efficiency.

challenges and Considerations

Despite the numerous advantages, the transition to a Smart Factory is not without challenges. These include:

- high initial investment: Setting up a Smart Factory requires a significant upfront investment in technology and infrastructure.

- data security: With increased Connectivity comes the risk of cyber-attacks. Ensuring robust data security measures is essential.

- Skill Gap: The move towards Smart Factories necessitates a workforce skilled in both traditional manufacturing and advanced digital technologies.

future prospects

The future of Smart Factories looks promising as AI technologies continue to evolve. With advancements in machine learning, IoT, and robotics, the capabilities of Smart Factories will expand further, making them increasingly autonomous and efficient. The integration of 5G technology is also expected to enhance real-time data processing and communication, further driving innovations in industrial Engineering.

Conclusion

Smart Factories represent the pinnacle of modern industrial Engineering, marrying AI with manufacturing processes to create highly efficient, dynamic, and cost-effective production environments. As the technology continues to evolve, we can expect Smart Factories to play an even more pivotal role in shaping the industrial landscape of the future.