IT in Textile Engineering: Innovations in Fabric Production

In today's fast-paced world, technology is transforming industries at an unprecedented rate, and textile engineering is no exception. Information Technology (IT) is revolutionizing fabric production, bringing about innovations that improve efficiency, quality, and sustainability. This blog explores the cutting-edge ways IT intertwines with textile engineering, paving the way for a smarter and more innovative fabric production industry.

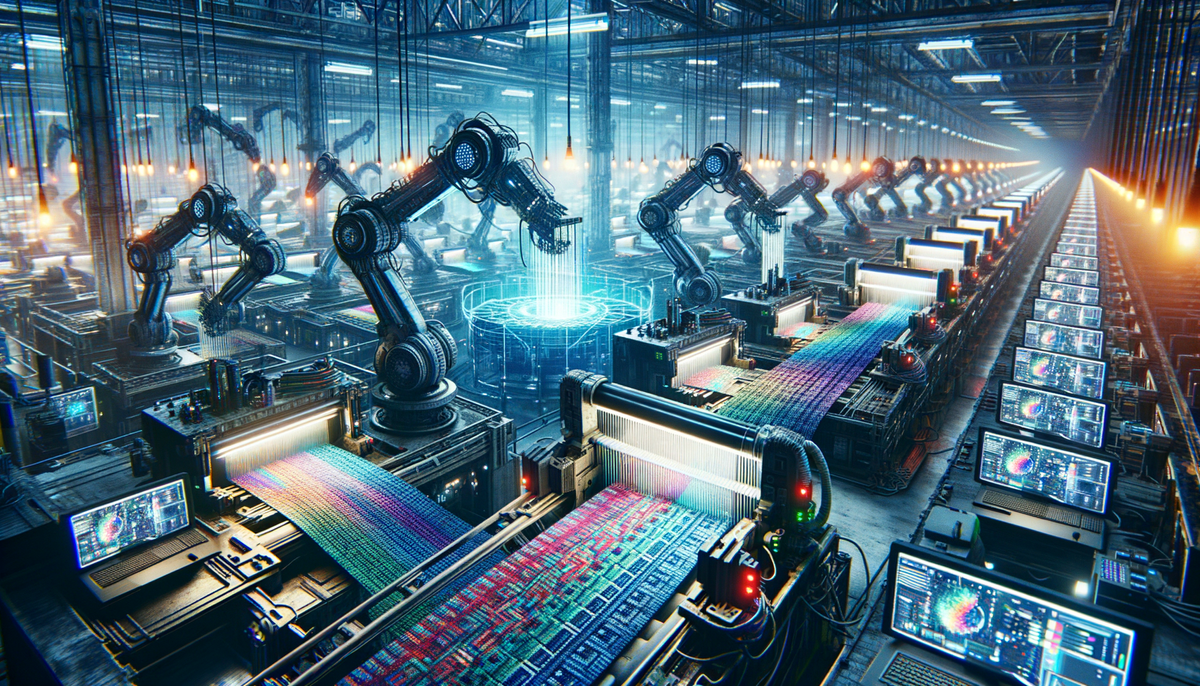

The Digital Loom: A Modern Take on an Ancient Craft

One of the most significant advancements in textile engineering is the digital loom. Traditional looms have been the backbone of fabric production for centuries, but digital looms bring a new level of Precision and speed. Using computer-aided design (CAD) software, textile engineers can create intricate patterns and designs that were previously impossible to achieve.

The digital transformation doesn't stop at design; automated looms can weave these patterns with incredible accuracy. This reduces the chances of human error, ensures high-quality output, and speeds up the production process. These advancements ultimately contribute to a more efficient and cost-effective textile manufacturing industry.

IoT and Smart Textiles: A Fusion of Fabric and technology

The Internet of Things (IoT) is another technological Innovation making waves in textile engineering. Smart textiles, embedded with sensors and conductive threads, offer functionalities beyond basic fabric. These textiles can monitor body temperature, heart rate, and other physiological parameters, making them ideal for healthcare and sports applications.

The integration of IT in these textiles allows for real-time data collection and analysis, providing valuable insights into user health and performance. This is particularly beneficial in medical textiles, where continuous monitoring can help in the early detection and management of health conditions.

Artificial Intelligence: Optimizing Fabric Production

Artificial Intelligence (AI) is playing a crucial role in optimizing fabric production processes. machine learning algorithms can analyze vast amounts of data to predict demand, manage inventory, and even control quality. AI-powered systems can identify defects in fabrics in real time, significantly reducing waste and ensuring that only top-quality products reach the market.

AI also aids in predictive maintenance of textile machinery. By analyzing machine data, AI can predict when a piece of equipment is likely to fail, allowing for timely maintenance and reducing downtime. This not only ensures a smoother production process but also extends the lifespan of the equipment.

3D Printing: customization at Its Best

The advent of 3D printing has opened new doors in textile engineering. This technology allows for the creation of custom fabrics with unique properties. Textile engineers can experiment with different materials and structures to create fabrics that are lightweight, durable, and tailored to specific applications.

3D printing also enables on-demand production, reducing the need for large inventories and minimizing waste. This customization capability is particularly appealing in the fashion industry, where designers can create bespoke garments for their clients, offering a unique, personalized experience.

Sustainable Fabric Production: An IT-Driven Approach

sustainability is a pressing concern in the textile industry, and IT is playing a pivotal role in addressing this issue. technologies such as digital dyeing and printing reduce the consumption of water and chemicals significantly. Automated systems can optimize resource usage, minimizing waste and reducing the environmental footprint of fabric production.

Blockchain technology is also being used to ensure transparency and traceability in the Supply Chain. Consumers can now verify the origin of their textiles and ensure that they are produced sustainably and ethically. This not only builds consumer trust but also encourages manufacturers to adhere to sustainable practices.

Conclusion

Information Technology is revolutionizing the textile engineering landscape, bringing about innovations that enhance efficiency, quality, and sustainability. From digital looms and smart textiles to AI and 3D printing, the integration of IT in fabric production is paving the way for a smarter, more innovative industry. As these technologies continue to evolve, we can expect even more exciting developments in the future, transforming how we produce and interact with textiles.